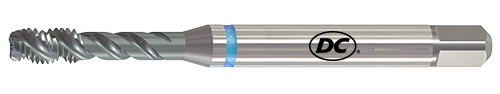

N - Normal materials

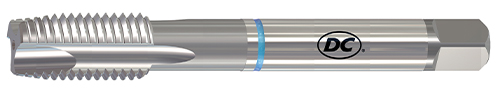

Feature

- The ultimate standard tool

- Availabe in blanc version, with DC "V" surface treatment or with TiN and TiCN coating

- Works on a wide range of materials < 850 N/mm2

QTAP - the DC Allrounder

Feature

- Perfect interaction between the cutting geometry, the improved conditioning of the cutting edges, the new VS coating against wear and the specific basic material

- For universal use in different kind of materials up to 1'150 N/mm2

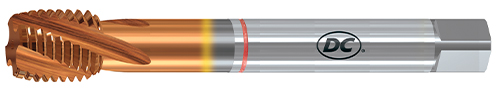

Z - Tough materials

Feature

- Version "V" - with DC "V" surface treatment, for use with cutting oil

- Version VS - with DC "VS" wear protective coating for use with emulsion or cutting oil

- Version Z.73VS - with internal coolant with frontal outflow

W - Soft materials

Feature

- W-DLC - for aluminium with a low silicon content (< 9 % Si)

- With yellow ring for material classification "W"

H - High tensile materials

Feature

- For short chip brass, phosphor bronze, gun metal, lead free brass

- For Duroplastics and glass fibre reinforced plastics

- DC "VH" wear-protective coating for high-tensile and abrasive materials

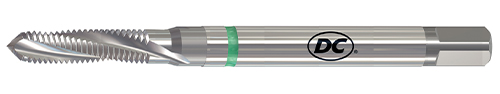

S - Special alloys

Feature

- For hardened / tempered alloy steels; ferritic and martensitic stainless steels; nickel alloys 2

- With DC "VS" wear-protective coating for general use

- With green ring for material classification "S"

SA - Special alloys (AERO)

Feature

- SA320-4 / SA350-3 - For special alloyed materials > 850 - < 1'150 N/mm2

- SA390 - particularly stable design for nickel alloy 3 > 1'150 - 1'600 N/mm2

- With green ring for material classification "SA" - AERO

STL – Machining titanium

Feature

- Innovative tool, patent pending - STL.81SUA-4

- Slow right-hand spiral flutes ~ 15° - STL.52SUA-3

- Tribology - coating specially designed with our partner to prevent sticking, in rainbow colour

- High, consistent tool performance

TL - Titanium alloys (AERO)

Feature

- With DC "VS" treatment to improve the sliding properties and to avoid cold welding

- TL.51VS - with interrupted thread for less heat generation

- TL.51VS - for through and blind holes < 2 x D

GG - Grey cast iron, cast-aluminium, magnesium alloys.

Feature

- Version NV with plasma nitriding + "V"

- Version TC with TiCN coating (Titanium-carbonitride coating)

- Version GG.53TC - with internal coolant with frontal outfolw and TiCN coating

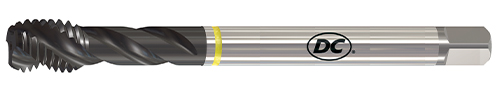

K - Swarf breaker

Feature

- Guaranteed safe tapping process with no swarf nests and wild chips

- With internal coolant with frontal outflow

- For all kind of parts with blind holes with tapping depth < 4 x D, preceded by a counter-bore.

N470V - Crown taps

Feature

- For through and blind holes

- Chip accumulation capacity of the recess: up to Ø 30 mm: 1.2 x D / from Ø 30 mm: 1.4 x D

- On request available up to Ø 160 mm

N5951 - Combination drill/taps

Feature

- Center, countersink, drill and tap with one only tool

- Ideal for use on CNC-machines, drilling and boring units, turret lathes and tapping machines

ZX - Alu-bronze alloys (Ampco®)

Feature

- Optimal for AMPCO® 21 / 22 with a hardness of HB > 280 - < 330

- Suitable for AMPCO® 18, 25 and 26 with a hardness of HB < 420

- With blue ring for material classification "Z"

What's next?

Use our tool finder to see all the range of product

Solutions

Our crafted solutions for every problem you might face

We guarantee economy of cost and extremely consistent, fault-free manufacture.

Services & Support

Swiss quality services

We offer you more than just the creation of precision tools, we provide complete support. Accreditation, metrology, test center... we accompany you at all times.